Aluminum Framing Systems are a flexible framing system with endless possibilities. The framers and trimmers can be cut to size on site which makes them the perfect method for any job big or small.

With so many options it can be difficult to design your frame exactly how you want it.

Here are some suggestions of ways to customize your own Aluminum Framing System.

The most common material chosen is 6061-T6 for aluminum extrusion which comes in 10 foot lengths that are 2 inches wide by 1/4 inch or 3/8 inch thick.

These sizes allow the framers and trimmers to be cut on site with a saw and then drilled for screws or nails.

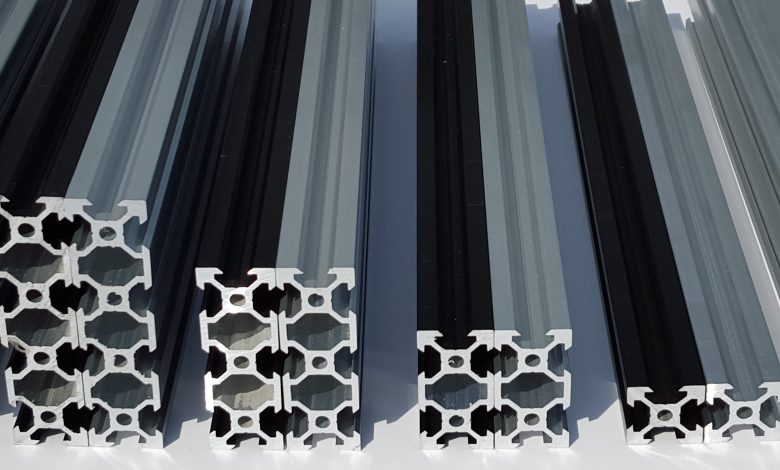

The standard anodized color of Aluminum Framing System is Mill (Silver). Other colors such as Bronze, Black and White can be ordered but this will add cost to your frame.

If you don’t mind having a silver frame with black accents you can simply paint the framer and trimmer black or any other color to match your home.

Anodized aluminum is fairly durable but it can be hit or miss when it comes to paint adhesion. So you may want to use a primer first and then a quality exterior grade paint that can take the elements. This will add durability and help the paint last longer.

Powder coating is also another option which will provide even more durability, color options and protection from the elements.

Powder coating comes in any color so it’s easy to match your aluminum frame with paint or have a custom color of your choice. Aluminum Framing System can easily be powder coated by most local powder coaters. Paint may chip eventually, but powder coating should never chip.

One of the most popular customizations is to add aluminum trim around windows and doors to match the Aluminum Framing System.

Aluminum extrusions are easily cut using a chop saw or other type of hand held saw or power tool. The jig shown in this link will help keep the saw square for an accurate cut.

Be sure to seal the edges of aluminum trim with a good grade of silicone to keep moisture out. Keep in mind that aluminum has relatively low heat resistance so any type of adhesive applied to bare extrusion may cause bubbling or blistering when exposed directly to high temperatures such as when using a soldering gun or torch to cut or join pieces.

Using plastic end caps will cover the sharp edges that are created when cutting aluminum extrusions. They are easy to install with an adhesive of your choice for a clean finished look. The following article shows how to make them yourself using standard acrylic coping trim found at any home improvement store in various styles and colors.

One of the best ways to design your Aluminum Framing System is to draw a sketch of what you want. It’s always easier to understand how it will all come together with a picture so you can see where framing members need to be cut, support members added and openings for windows or doors.

For more design and customization assistance, contact Minitec Profile Systems.