In order to efficiently transport heat from one conduit to another, heat exchangers are pieces of hardware. A strong wall separates the media, preventing direct contact between them. These have extensive use in space heating, refrigeration, air conditioning, power plants, chemical plants, petrochemical plants, petroleum refineries, natural gas processing, and sewage treatment. A heat exchanger is best shown in an internal combustion engine, where a circulating fluid like an engine coolant runs through radiator coils and air flows through the coils, cooling the coolant and warming the incoming air.

Though the Heat Exchanger Makers in USA are entirely different in design and construction, they also might be of single- or two-phase type, but their modes of operations and effectiveness are majorly determined by the direction of the fluid flow within the exchanger.

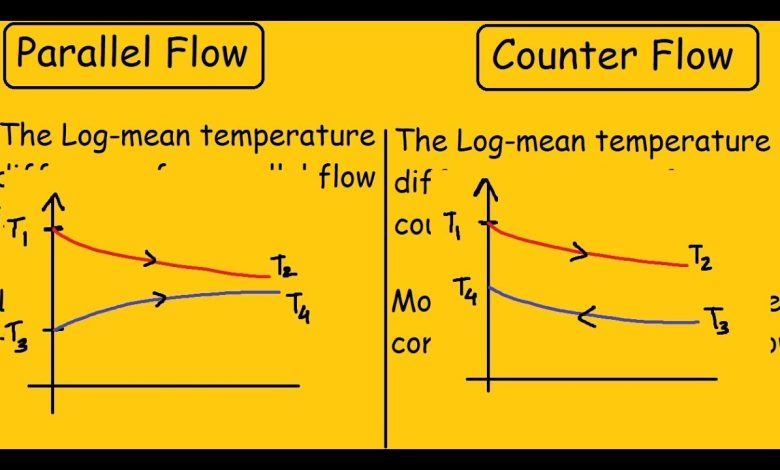

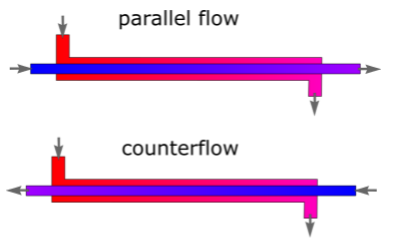

There are primarily two types of flow paths within a heat exchanger:

- Parallel Heat Flow

- Counter Heat Flow

Parallel Heat Flow:

In a parallel heat flow, the direction of the working fluids flows in a similar direction. The name of both the working fluids is shell side fluid and tube side fluid. In double-pipe heat exchangers, parallel heat flow is common.

Counter Heat Flow:

Both the shell side and tube side working fluids flow in the opposite direction.

The graphic shown below clearly depicts both flow heat exchangers:

Advantages of Parallel Flow:

- The parallel flow heat exchanger maintains a uniform temperature of both shell and tube fluids throughout. This can be used when the aim is to maintain an insignificant temperature gap in a heat exchanger.

- When there is a significant temperature gap, the cold-fluid temperature remains colder compared to the hot-fluid temperature.

Disadvantage:

- The huge temperature difference at both ends results in intense thermal issues. The contradicting expansion and contraction of the construction materials due to varied fluid temperatures can lead to material failure.

- The temperature of the cold fluid escaping the heat exchanger never exceeds the lowest temperature of the hot fluid. This becomes an opposing characteristic of this flow pattern, since the main purpose of this flow pattern, is to raise the temperature of the cold fluid.

Advantages of Counter Flow:

- The counter flow heat exchanger maker is the most common type of flow pattern in shell and tube heat exchangers, owing to its efficiency. This flow pattern permits the greatest temperature difference between fluids. Furthermore, unlike in parallel flow exchangers, the cold fluid can reach the hot-hottest fluid’s temperature because it exits at the end where the hot-fluid enters.

- The difference in temperature in counterflow configurations is more uniform across the entire exchanger, which lowers the thermal stress and could otherwise lead to shaking or motions that can damage the equipment.

Disadvantages of Counter Flow:

- Confined cooling towers are usually expensive due to enumerable copper coils with greater heat exchange performance.

- The temperature in the northern region in winter is relatively low. Inadequate anti-freezing procedures might result in the cooler completely freezing over and cracking.

How Counter-Flow heat exchangers are better than Parallel flow heat exchangers?

The temperature difference is, that less thermal stress is there in the heat exchanger and the counter-flow heat exchanger exactly does that.

- The counter-flow heat exchanger can raise the outlet temperature of the cold fluid.

- It circulates a uniform rate of heat transfer since there is a uniform heat temperature throughout.

Heat Exchanger Equipment Suppliers:

PexSupply.com-Heat Exchangers, Hydronic Heat Exchangers, Flat Plate Exchangers: GEA Flat Plates FP Series of Heat Exchangers designed for hydronic heating, snowmelt (glycol), portable hot water, multiple industrial processes and used were efficient, reliable and compact fluid heat exchangers are required.

These heat exchangers are 100% stainless steel and include heavy-duty male pipe thread connectors and mounting studs that meet certain criteria. The heat exchanges offered by us are UL and CRN listed.

Lytron Inc- Heat Exchangers: They provide custom heat exchangers and standard heat exchangers.

International Site for Spirax Sarco-Oversized Heat Exchangers:

Heat exchangers are mostly bought oversized for the due requirement. A vast range of heat exchanger-related equipment is provided by Spirax Sarco.

Heat Exchanger makers in USA:

Air Products and Chemicals Inc: They are one of the leading refining, chemical, metal, and electronics manufacturers in the US. Industrial materials and gases, as well as heat exchangers and control devices, are also provided for industrial use by them. They meet the needs of their customer with more than 750 production facilities. They are located in Allentown, Pennsylvania.

Xylem Inc: They are a water-based technology manufacturer, they manufacture instrumentation pumps, treatment systems, and heat exchangers. They provide analytics, dispensing, freezing, processing, and heat transfer applications and are located in Rye Brook, New York.

SPX Heat Transfer Inc: They are based out of Bethlehem, Pennsylvania, and design and manufacture heat exchangers for the geothermal and other power generation industries. They also provide heat transfer equipment, services, aftermarket parts, and retrofitting of Heat Exchanger Makers in USA, as well as condensers, heaters, dampers, ejectors, and other products.

Heat Exchanger Manufacturer:

Alfa Laval AB: Alfa Laval AB primarily produces heat transfer, separation, and fluid handling equipment. The company serves the industries of energy optimization, environmental protection, and food production. Heat transfer (heat exchangers), fluid handling (pumps and valves), and separation are its three product lines (centrifuges). Its services and equipment aid in the optimization of processes like heating, cooling, separating, and transporting products.

API Heat Transfer, Inc: The Heat Exchanger Equipment Supplier in the USA provides air-cooled, pre-engineered, shell, tube, and thermal systems. This company also manufactures power and marine boilers, pressure and non-pressure tanks, processing and storage vessels, weldments, and other related equipment.

Danfoss: They majorly exude mechanical and electronic components for distinct equipment. Comparatively used in multiple sectors. More than a third of the company’s revenue comes from a major power solution unit. The hydraulic systems and electronic controls for off-highway vehicles. Refrigeration and air-conditioning equipment, heating equipment, and commercial compressors are among its other divisions.